How the Mass Production of 3D Printed Face Masks is Combating COVID-19

As COVID-19 continues to impact the world, the need for 3D printing solutions to provide supplies to the medical community increases drastically. Many creative and determined heroes are turning to 3D printing to support the medical community at this time to help combat the shortage of necessary supplies. This new initiative aims to connect the needs of the medical community with 3D Printing and their extensive network to support requests for supplies quickly and efficiently.

3D printing is now being used by many to create facemasks and protective shields. These case studies show how effective and efficient 3D printing can be for mass production.

WASP Protection Ventilated Helmet

WASP have designed and created an air-conditioned, ventilated helmet with a controlled space. A positive pressure protective Helmet. The result of a few days of experimentation has allowed WASP’s protection ventilated helmet to pass, in only three days, from a prototype to the first production for internal use, all thanks to digital manufacturing.

This device wants to fulfil the prerogative to be in close proximity with another person, without the risk of contamination. The ventilated helmet is made of light and transparent plastic material that is easy to wear and creates a personal protected space. This helmet uses a battery powered fan to provide fresh, clean air that comes from above, while small holes near the ear allow sound to enter.

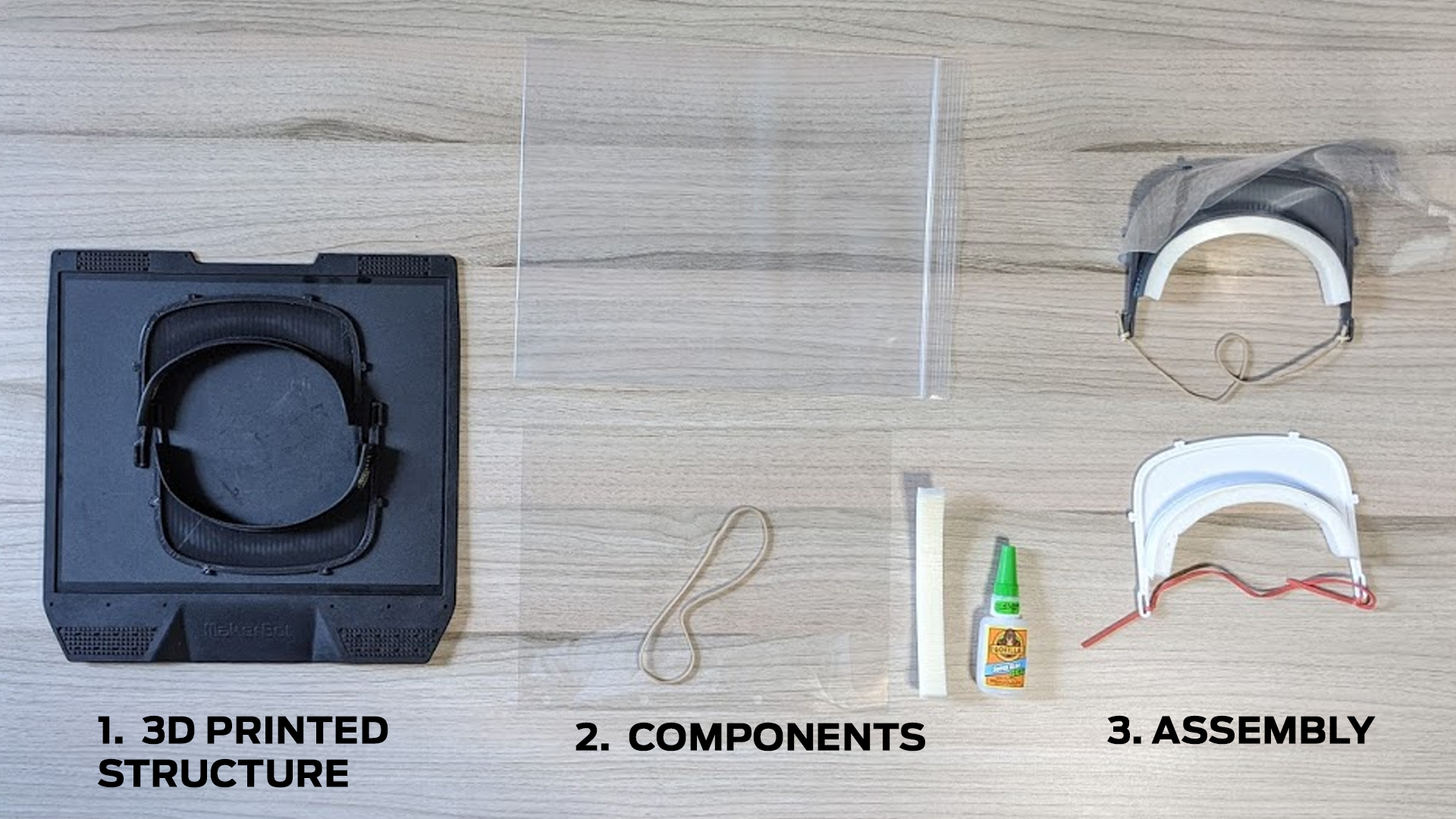

MakerBot 3D Printing Farm

MakerBot is making sure that they are getting stuck with helping the medical community at this challenging time to help combat the shortage of necessary supplies. This initiative aims to connect the needs of the medical community with MakerBot and their extensive network to support requests for supplies quickly and efficiently.

MakerBot are printing face shield visors and other medical supplies in-house and delivering them for assembly, currently MakerBot’s output stands at 460 units per day and an overall team effort of 1000 units per day, they are working with the masses to help hospitals, medical professionals and other organisations who need medical supplies.You can submit your requests for equipment via an online request form on the MakerBot website.

MakerBot are also collaborating with students, Medical Doctors and Designers to print samples for the community, provide design feedback or answer questions about what can and cannot be done with 3D printing. They are working with Columbia University Libraries to produce, assemble and deliver face shields to NYC hospitals and workers on the front lines. MakerBot users and the 3D printing community are also submitting offers to assist in the printing of PPE gear. Instruction on the printing and assembly of face shields, donating filament and hardware when applicable is also being given.

MakerBot are quickly helping to fulfil demand for printers required to produce needed parts for the prevention of COVID-19, you can find out more about how to get involved here.

Rolem

Rollem Ltd of Rotherham, specialist manufacturers of innovative, bespoke print finishing solutions for printers around the world has been in business for over 90 years, and unsurprisingly owes its’ long years of success to exploiting technical innovation to drive their continuing supply of highly accurate, flexible, productive systems.

An early adopter of 3D printing, Rollem runs a suite of MakerBot 3D printers from 5th Gen to the latest members of the MakerBot Method family of printers. Normally printing bespoke or low volume or custom parts for customised system modules, recent events have pared Rollems’ normally vibrant working environment back to a skeleton crew focusing on printing facemask parts for the NHS as part of a manufacturing and distribution network to help meet PPE demand during this national pandemic.

You can read more about Rolem and their initiative here.