WASP's 3D Printed Face Masks

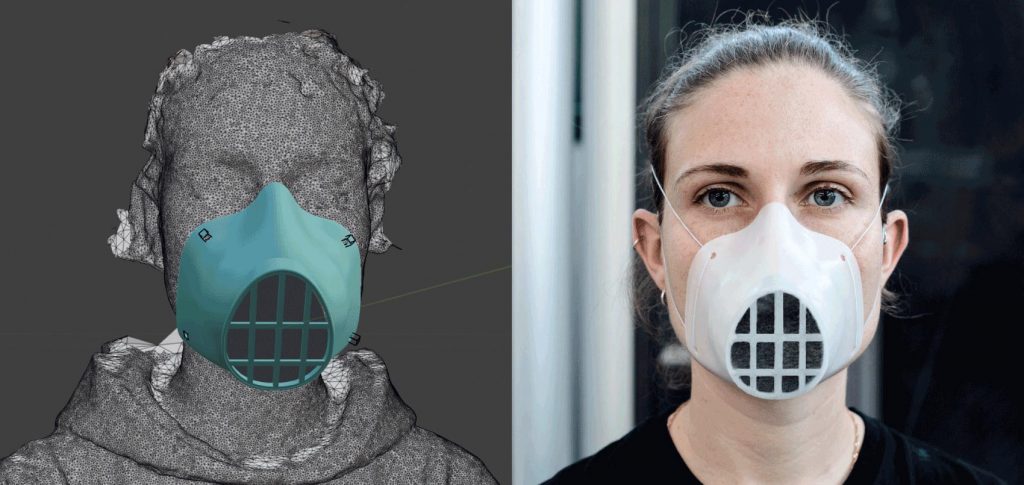

3D Printing can work hand in hand with 3D scanning, this is what WASP are doing to create custom, personalised face masks that hold a replaceable filter.

WASP have developed a process that, starting from the 3D scan of the face, allows you to create and customise a 3D mask tailored to each operator. The subject can be scanned by photogrammetry with a cellphone 1 meter away. The photos are then processed for the reconstruction of the person's face mesh. After applying a basic model on the face mesh, the mask is made perfectly ergonomic by modelling it in 3D with the My Face Mask Blender add-on. The idea is a 3D mask that can be disinfected and used multiple times. For this there is a joint in the front area that makes the filter interchangeable , this allows you to choose the filtering mode depending on the work you have to face.

The material used for printing in the video is PCL: polycaprolactone. It is a biomaterial that can remain in contact with the skin. A biomaterial that is already used in the medical field, melts at 100 degrees , does not shrink and there is no need for a hot chamber to print it. At the end of the print by immersing the mask in hot water at about 60 ° it is possible to change its shape by adapting it further to the face.

WASP are using the Delta Wasp 4070 Industrial 4.0 3D Printer which you can learn more about here.